Table of Contents

If you’re new to woodworking and turning, it can be difficult for a beginner with no knowledge about the different types of lathes on offer. There are many varieties out there: some suitable only as gifts or models but others more appropriate if your ambition is high-level work such as furniture making and/or intricate projects like turning pen blanks to make bespoke writing pens.

What is a lathe?

A lathe is a machine tool that shapes pieces of metal, wood or other materials by rotating them against a cutting tool. Lathes are used in manufacturing, metalworking and woodworking industries. They can be manual or powered.

Lathes are machines that spin a workpiece (wood or metal) to produce shapes that are typically cylindrical in shape. A lathe is used for woodworking and turning: the headstock holds one end of an axis with threads on it, called ‘spindle’ or ‘mandrel’, which rotates at high speed under power from belt/pulley drives.

The headstock is rotated by a drive belt or direct from an electric motor, which can be through the use of gears/a pulley system to give different ratios and therefore speeds for each turn; this speed dictates how fast workpiece turns on its axis during machining operations: faster means more material removed per revolution (equivalent to larger diameter circles)

The operator applies a tool to the material being machined. A variety of cutting tools are available for machining different materials: from the commonly used gouge, which is a chisel-shaped tool with convex sides designed to remove material on either side; or flat scraper (with straight edge) that can be glued onto woodworking lathes in order cut across workpiece.

A tool rest also provides stability and support when working near live centre Commonly manufactured products include turning decorative bowls/fruit platters outwards towards rim where shapes become more difficult due to this shape being tapered at an angle away form spindle axis–or turned using right hand while guiding it by left index finger around circumference avoiding sharp points as well any sudden movement during process so not ruin product through one slip off point causing circular indentation.

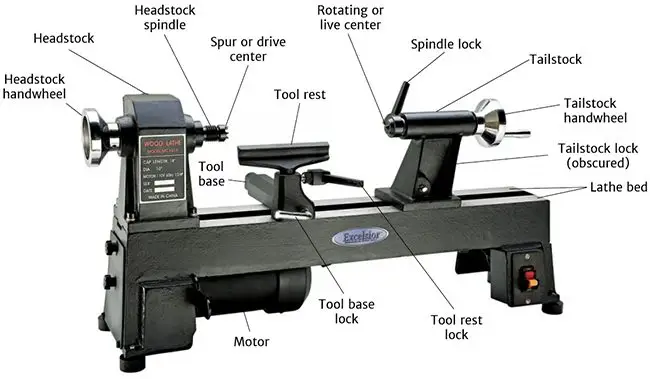

The component parts of a lathe

The headstock holds one end of an axis with threads on it, called a ‘spindle’ or ‘mandrel’, which is rotated by a drive belt or direct from an electric motor, which can be through the use of gears/a pulley system to give different ratios and therefore speeds for each turn; this speed dictates how fast workpiece turns on its axis during machining operations: faster means more material removed per revolution (equivalent to larger diameter circles)

You can then add a number of jigs or chucks onto the headstock which will allow you to hold the material that you are working on, depending upon the size and shape of the workpiece.

The tailstock provides support for long pieces of material, and can also be used as a centre when not rotating things like pen barrels etc to machine them from both ends.

The lathe bed is the long section between the headstock and the tailstock. Its purpose is to provide support for the workpiece tool rest, which is the part of the machine which supports your tool.

The operator applies this cutting edge onto material being machined via revolving chisel-shaped cutter called gouge between centres providing superior precision control over cut depth than handheld sawing methods – producing flat surfaces more accurately at higher speeds without any radial pressure exerted upon workpiece enabling smoother surface finishes.

Why would you want to use a lathe?

Lathes are used for a variety of reasons. Lathe work is often done to create pieces that will be turned into bowls, platters or other products that are round such as vases and lamp bases – though there’s no limit in what can be made from the lathe with solid wood. This is a task that is just not possible using other tools.

There are other uses for a lathe as well. The machine itself is valuable to have around the shop or home because it can be used to make parts for other projects. Making a round tenon on a piece of square stock, for instance, is a challenge not easily solved by other methods.

The lathe also comes in handy when sanding your finished piece as the lathe spins whilst you sand.

Applying finish in this way is also made easier by the lathe as it means that you can do all surfaces at once, whilst the lathe spins your workpiece.

Which type of woodworking or turning project are you looking to undertake?

From creating bowls, round boxes, pens, candlesticks, lamp holders, or small decorative parts, to producing large table and chair legs (or any other furniture), there are many projects that can be accomplished with the lathe including:

- Spindles – Spindles are often used as table legs or as other decorative components for ornamentation, creating candle holders or maybe lampstands.

- Bows and Platters – The lathe is also used to create decorative and functional pieces that need a round shape. This includes making bowls, platters or similar items from wood as well.

- Round Boxes – Round boxes are usually used for decorative purposes, but they can also be very useful in storing things like change or other small items such as rings or jewellery.

- Pens – Lathes can also be used to make pens from ‘Pen Blanks’ or other small items that require a round shape.

How much space do you have available for your new lathe and its accompanying tools?

You’ll need to think about the size of your projects and how large a lathe you want when purchasing one for yourself as an addition to your workshop. For example, if you’re a beginner who’s just starting out with woodworking and want to make small projects, then an option like the Jet Mini Lathe is perfect.

If space isn’t too much of a concern for your new lathe in general then consider purchasing the best one that you can afford at the time, as there are multiple different size options and you may find that you out-grow a smaller lathe in the future.

What is the cost range that suits your needs best?

This will help you narrow down your options to a selection of lathes that includes what features are the most important for completing projects.

The cost range is anywhere from £150 -£2500, with an average starting price around about £500. As these prices vary widely and depending on whether or not it’s new versus used one should research costs before making purchase decisions based solely off this information alone! The best way would be by asking friends who have purchased them as well if they’re willing provide some insights into their experiences in using different brands/types such things like how easy-to use were there tools?

Summary

The lathe has many uses and is one of the most versatile tools in any woodworkers’ arsenal, so it’s no wonder why beginners might have trouble figuring out which type they should use! The first thing you’ll need to decide when choosing a lathe for your project will depend on what kind or object or projects you are producing: either smaller turned pieces such as bowls; larger projects like tables legs with decorative patterning.

Conclusion

Hopefully, this post has given you a good overview of the different types and considerations when choosing lathes for your workshop. If not, then make sure to read up on more in-depth articles that will help answer any specific questions or concerns and read plenty of product reviews found both on this website and the internet.