Table of Contents

There are a few challenges to finishing purpleheart wood, but there is hope for the woodworker who is willing to put in the time. In this article, I’ll discuss issues such as sanding in between coats, working under UV light, and getting a gummy resin finish. Once you know the basics, you can begin the finishing process. If you’re new to purpleheart wood, read on to learn how to start the process and get the best results!

Challenges of working with purpleheart wood

While the visual appeal and strength of purpleheart wood are unsurpassed, the material can also pose a few unique challenges. It is susceptible to insect infestations and is not suited for use in water. Furthermore, it is difficult to plane without causing tear out. In addition, it tends to dull your blade and other cutting tools after prolonged use. Therefore, careful preparation is necessary before starting a project. Weigh all of these advantages and disadvantages before you decide to use purpleheart wood.

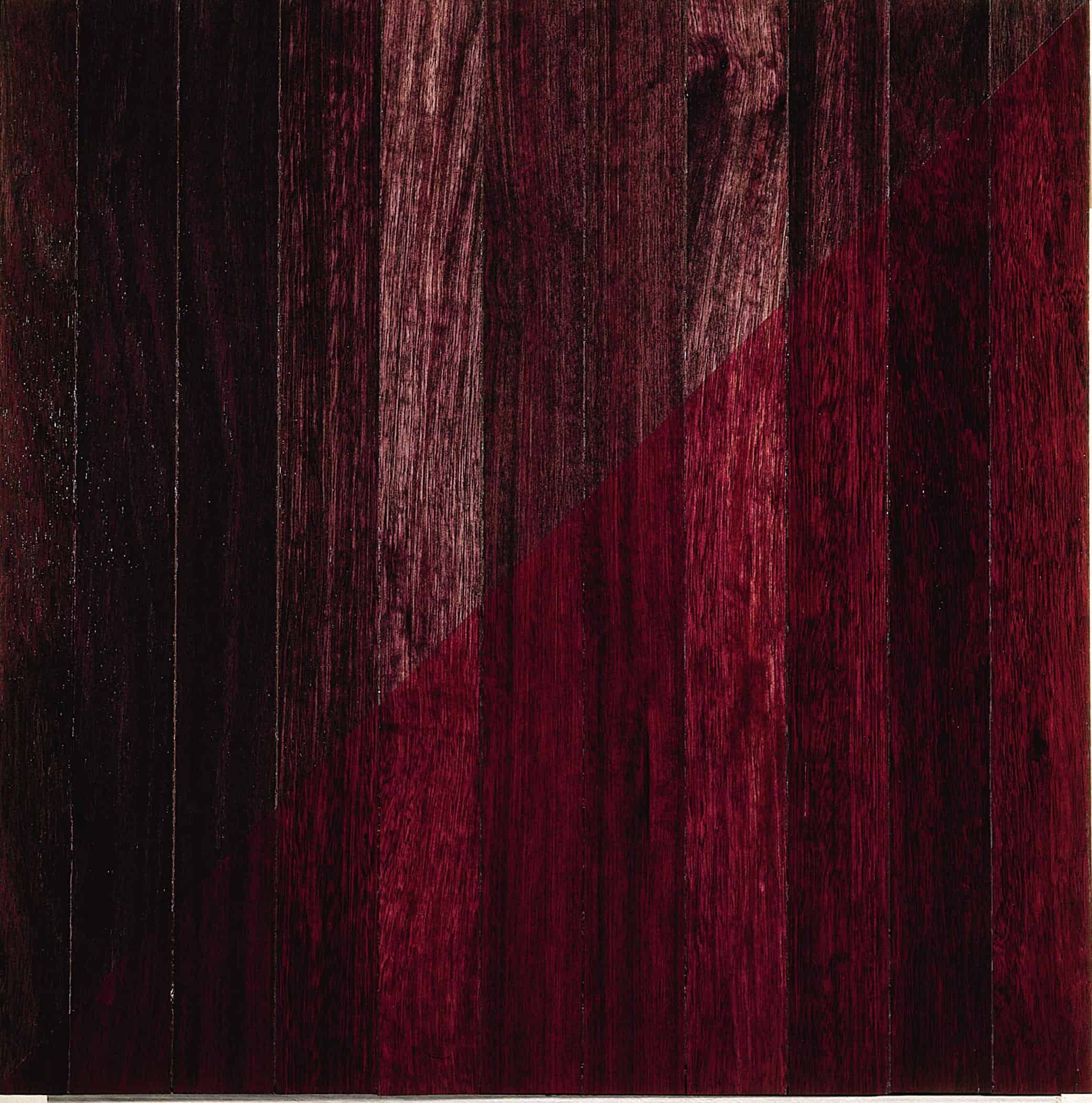

Because of its unusual colour and appearance, purpleheart wood is a rare and valuable material. It is also difficult to work with due to its gummy resin that can jam machinery and clog tools. However, despite the challenges, it is widely available and features reasonable widths and thicknesses, making it ideal for flooring, cabinetry, accent pieces, and speciality wood items. Due to its limited supply, you can find plenty of this exotic material in the US, but the price is high. It can cost up to $14 per board foot.

The main drawback of working with purpleheart wood is that it has a high degree of sensitivity. This wood is highly susceptible to fungus and can cause a number of health issues. For example, it can be highly flammable. To avoid these risks, you should avoid using purpleheart for glueing or applying adhesives. In addition, you should avoid touching the wood while working with it.

The best way to finish your projects made of purpleheart wood is with clear shellac sanding sealer or lacquer. These two finishes are durable and don’t yellow over time. The wood also maintains its vibrant colour for many years. It’s one of the most expensive types of wood, so if you can find a supplier, you can purchase a few boards at a time.

Because purpleheart wood has a unique colour, it can be difficult to blend and contrast with other types of wood. Therefore, many people choose to experiment with different woods before deciding on a particular wood for their projects. Depending on the grain and texture of the wood, different combinations can be created. The end results can be very varied, however, and they can result in products that are very different from what you were expecting.

UV light

Many people have noticed the stunning colour change of UV light finished purpleheart wood. In some cases, this wood can return to its original deep purple colour after the UV light finishes are applied. In other cases, the UV light can make the wood turn brown. In both cases, it’s best to apply a UV light finish before the final finishing. Here are some tips to achieve a stunning result from this wood. Here are some ways to transform the colour of your purpleheart wood.

First, determine the species of wood you are using. Purpleheart wood is a beautiful exotic wood, but it can pose some unique challenges. For instance, when heated, it produces a gummy resin, which clogs tools and complicates machining. Because of this, it can be difficult to plane without tears. Also, this wood has a moderate dulling effect on cutters. Finally, consider the odour of this exotic wood. Some species emit a pungent smell.

Peltogyne is a tree genus that has about 20 species of wood. The wood from this genus is similar to wood from other species, but it’s a distinct species with a uniform distribution. These trees grow to a height of 30-50 m (100-160 feet) and have linear, symmetrical boles between five and ten centimetres. The fruit of the tree is a pod containing a single seed.

When exposed to ultraviolet light, purpleheart wood will darken from a dull grey tone to a deep eggplant purple. It is strong enough to be used for furniture, but it is also difficult to break. Its Janka rating is 2520, meaning that a steel metal ball would need to exert 2520 pounds of force to penetrate into the wood. The main way to recognize purpleheart wood is its distinctive colour. When exposed to sunlight and air, it begins to glow in a rich purple hue.

If you’re building a wooden staircase, purpleheart wood may be your best bet. The hardwood is durable enough to withstand a variety of outdoor conditions. Although the wood is relatively expensive, it’s a good option if you’re building a wooden stair. This wood is available in many different sizes and styles, so you’ll have a wide variety to choose from. It’s also an excellent choice for flooring and cabinetry. It is also great for accent pieces and wood stair parts.

Need to sand between coats

If you have a plan to use purpleheart wood on a project, you must be sure to sand it properly. If you don’t, the purple colouration may fade into a dingy reddish shade. To preserve the natural colouration, you must seal the wood using a clear shellac sanding sealer. Zinsser’s Universal Sanding Sealer is an all-natural product that dries within minutes in low humidity.

This type of wood is difficult to cut because the grain is interlocking. To make cutting purple heart wood easier, you must use sharp tools with fine grits. You must also pre-drill the wood before applying any glue or polish. A Dremel will work fine for light cuts, but heavier cuts will likely result in burned wood. The resins in purple heart wood can cause the wood to burn.

A clear lacquer finish will help protect the wood from oxidation and will keep the colour vibrant for years. One of the options for lacquer is Watco’s Clear Lacquer Finish. It comes in satin and semi-gloss finishes, and both look good on purple heart wood furniture. To prevent yellowing, a clear lacquer can be used as a base coat.

The reason why Purpleheart changes colour is because it absorbs oxygen. If the wood is exposed to UV light, the pigments will break down. If the wood is exposed to light, the colour will change to a dark brown colour. Then it will age to a silver colour. But it is best to sand the wood before applying a finish coat. You can apply a final coat of lacquer only after the sanding sealer is completely dry.

The second advantage of purpleheart wood is its durability. Its strength makes it a great choice for construction projects. Its Janka rating of 2520 is excellent, and a steel metal ball would take 2520 pounds of force to bury itself in it. In addition to being durable, purpleheart wood accepts wood glue well and is very resistant to decay. When properly applied, this wood is a great choice for outdoor applications.

Getting a gummy resin finish

Using Purpleheart wood for furniture projects can be a bit tricky, due to its gummy resin finish. The gummy resin can get in the way of tools and complicate machining. Although it’s not toxic, it may cause a reaction in small numbers of humans and animals. As such, it should be treated with caution and care. Here are some tips to avoid burning your fingers while machining the wood.

First, let the wood dry. When using purpleheart wood, be sure to use a finish that will protect the wood from oxidization. Waterborne finishes will darken the wood less than oil-based finishes. You can also use marine-grade finishes, which contain UV inhibitors. Lastly, you can use a lacquer finish, which will hold colour longer than a water-based one.

If you’re working with a fresh piece of Purpleheart, you should apply a clear shellac sanding sealer. You can also use Zinsser’s Universal Sanding Sealer, which is all-natural and dries in minutes even at low temperatures. This product is ideal for sanding purpleheart wood. If you plan to use the piece outdoors, you can also apply a layer of gummy resin over it.

Once the varnish has dried, you should apply a coat of gummy resin. Purpleheart wood is one of the densest and strong trees on the market. However, it’s hard enough to dull cutting tools and causes tear-outs. However, it’s easy to glue and polish. And because it has a regular grain pattern, it’s easy to find a finish to match your finished piece.

It’s important to use proper tooling when sanding Purpleheart wood. It’s important to use a sharp plane to avoid tear-out, but it’s not a guarantee for success. You should also pre-drill when using end-of-board screws. By doing so, you’ll avoid splits and breakage. And make sure your blades are sharp enough to cut through the wood.